Completely fabricated and machined in our Portland facilities, for shredding metal using replaceable wear parts.

Stainless steel ship propellers ready to be machined on our 22 foot diameter lathe.

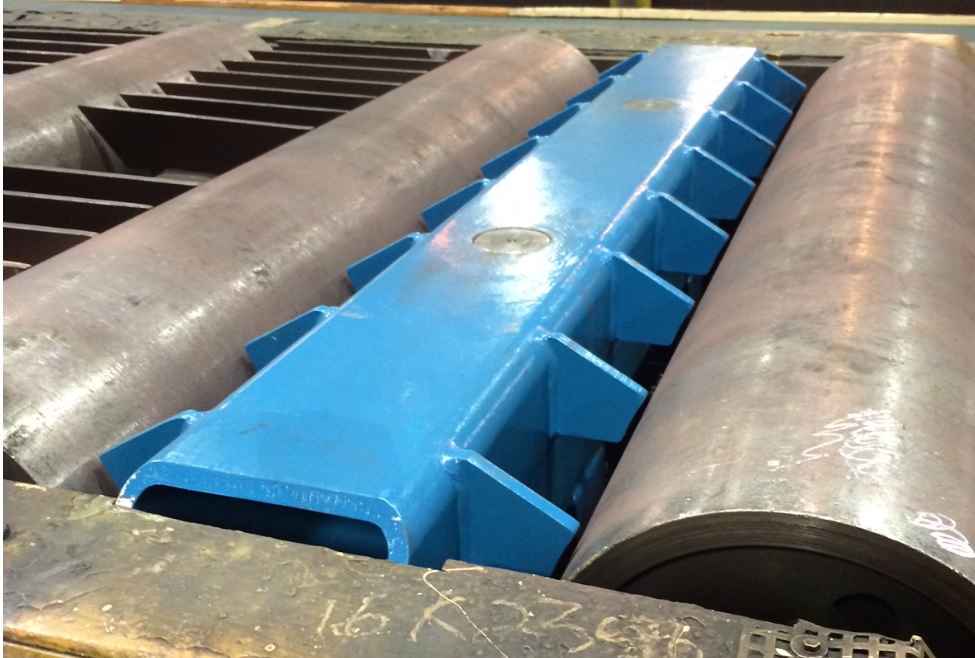

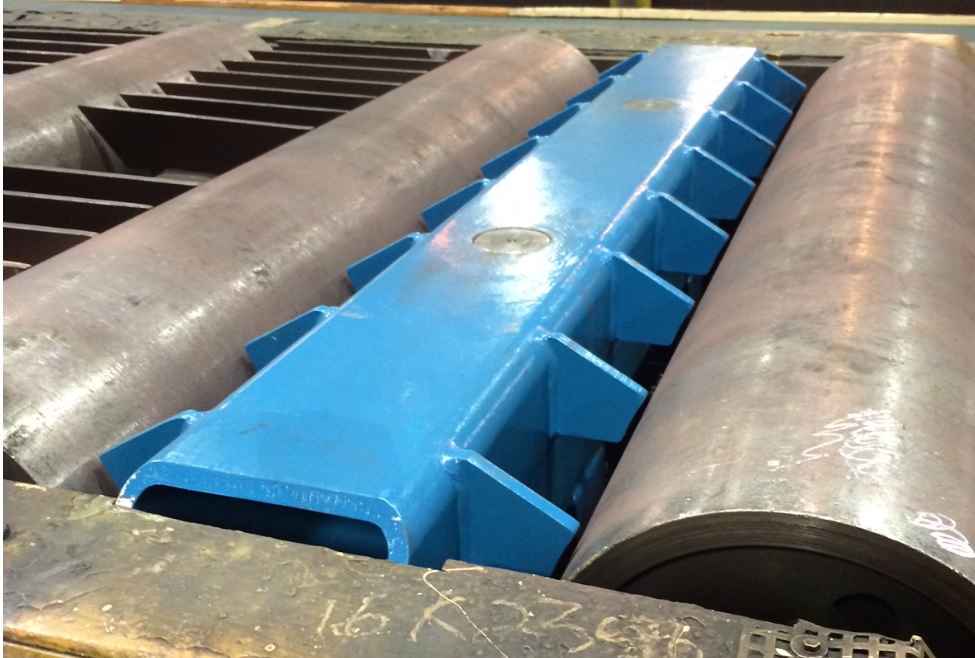

Furnace walking beam for the steel mill industry.

A long machine base being milled on our large vertical milling machine.

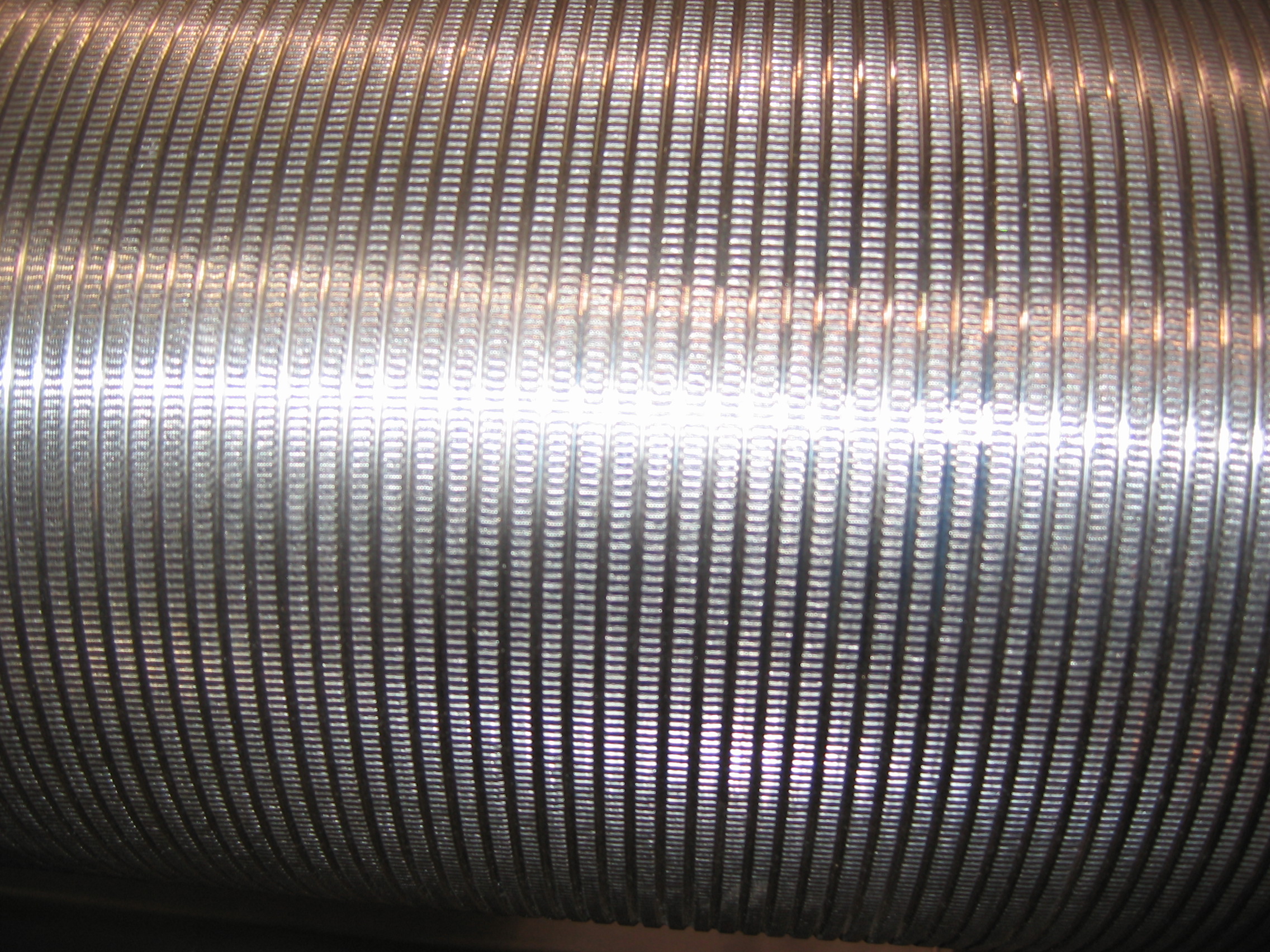

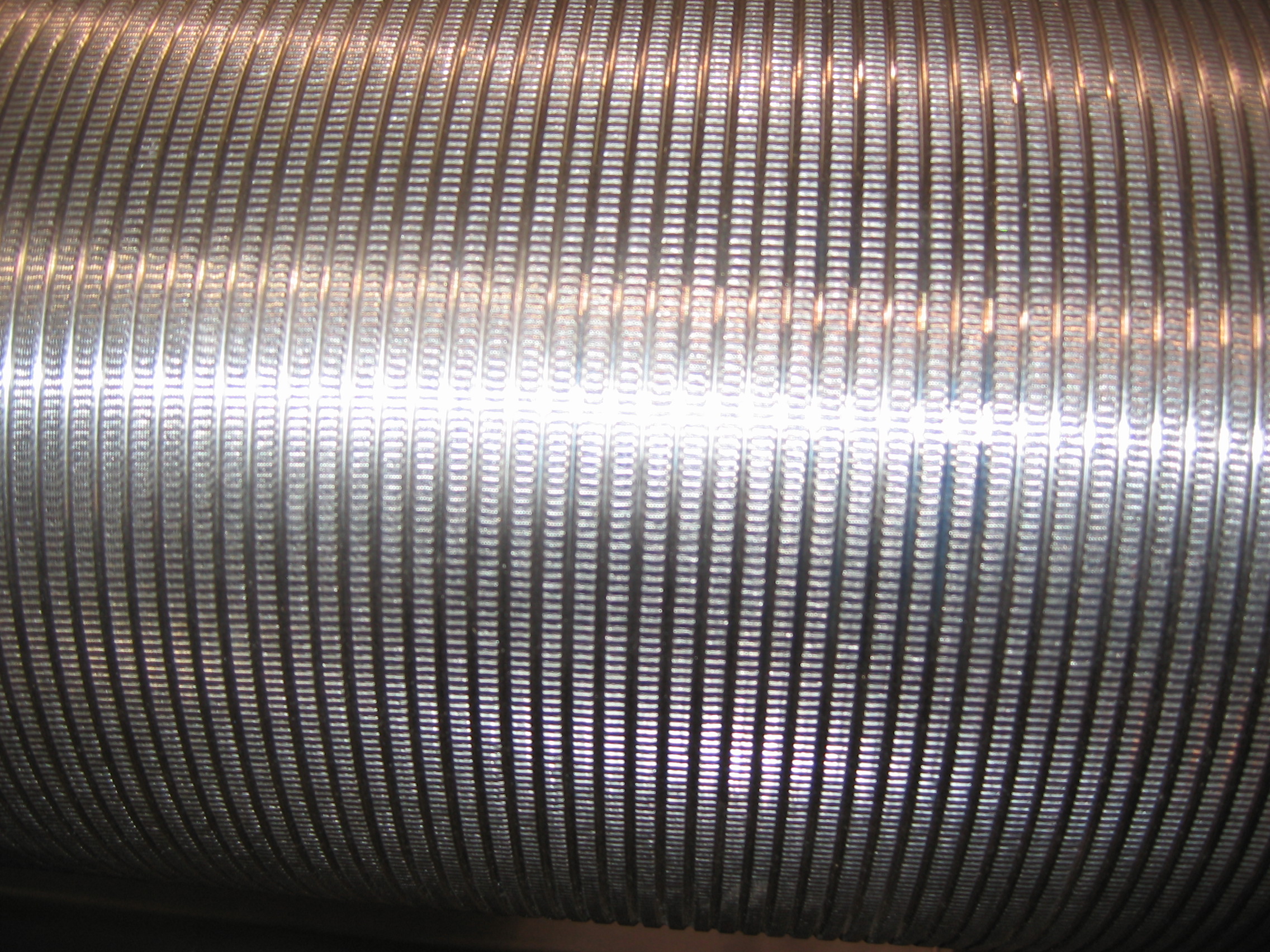

Wide view of a knurled roll.

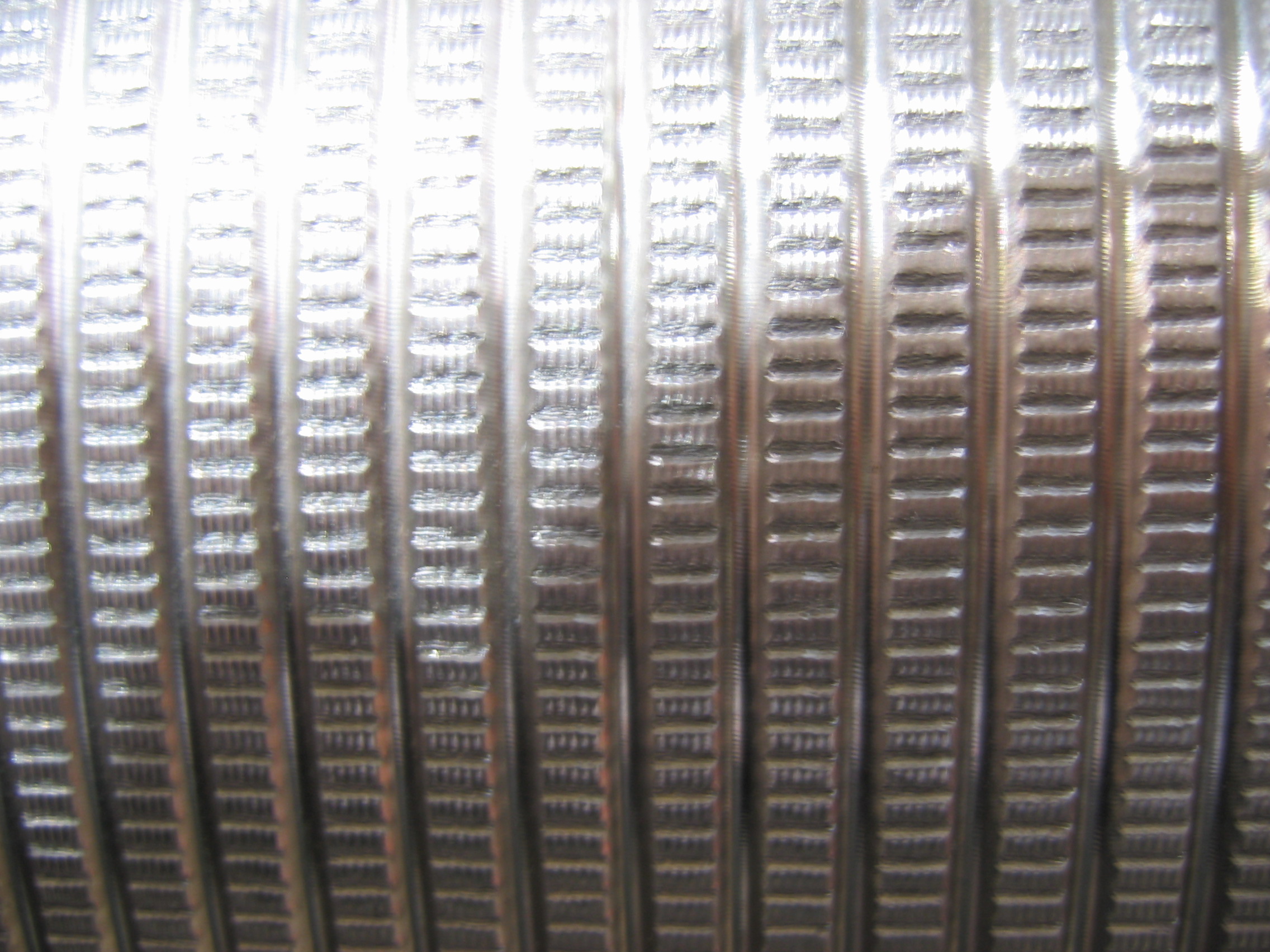

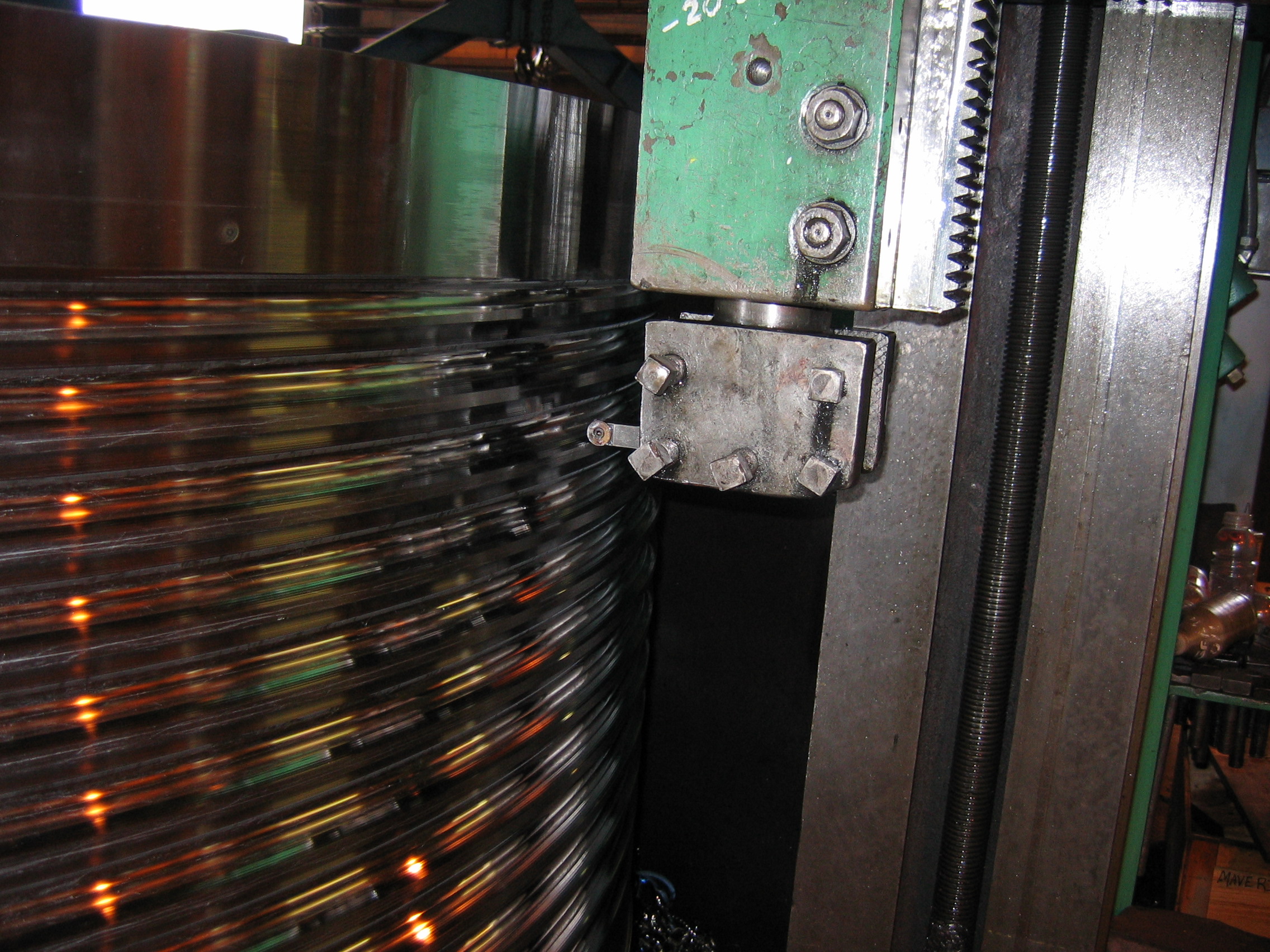

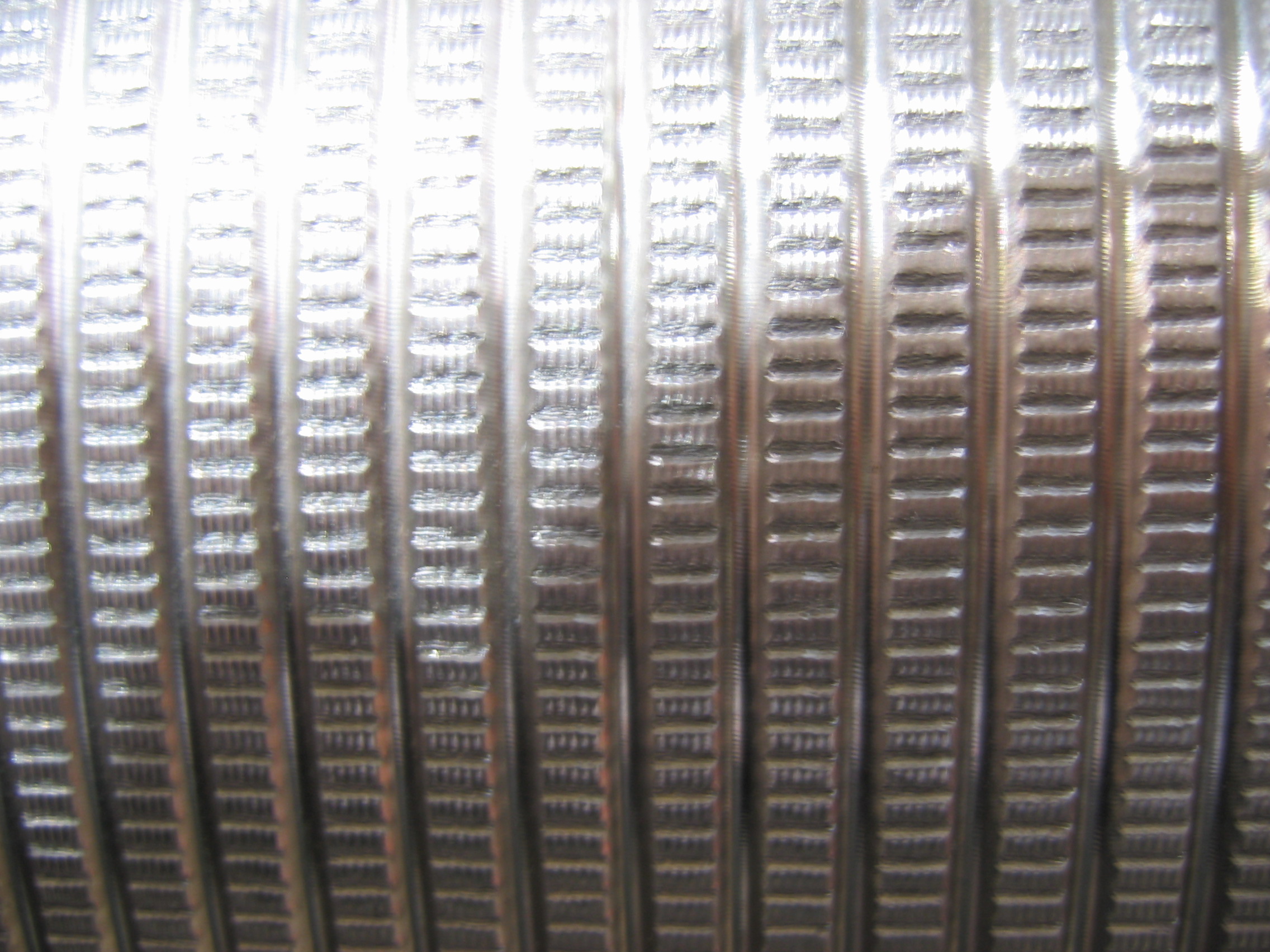

Close up of a fine pitch knurl on a roll.

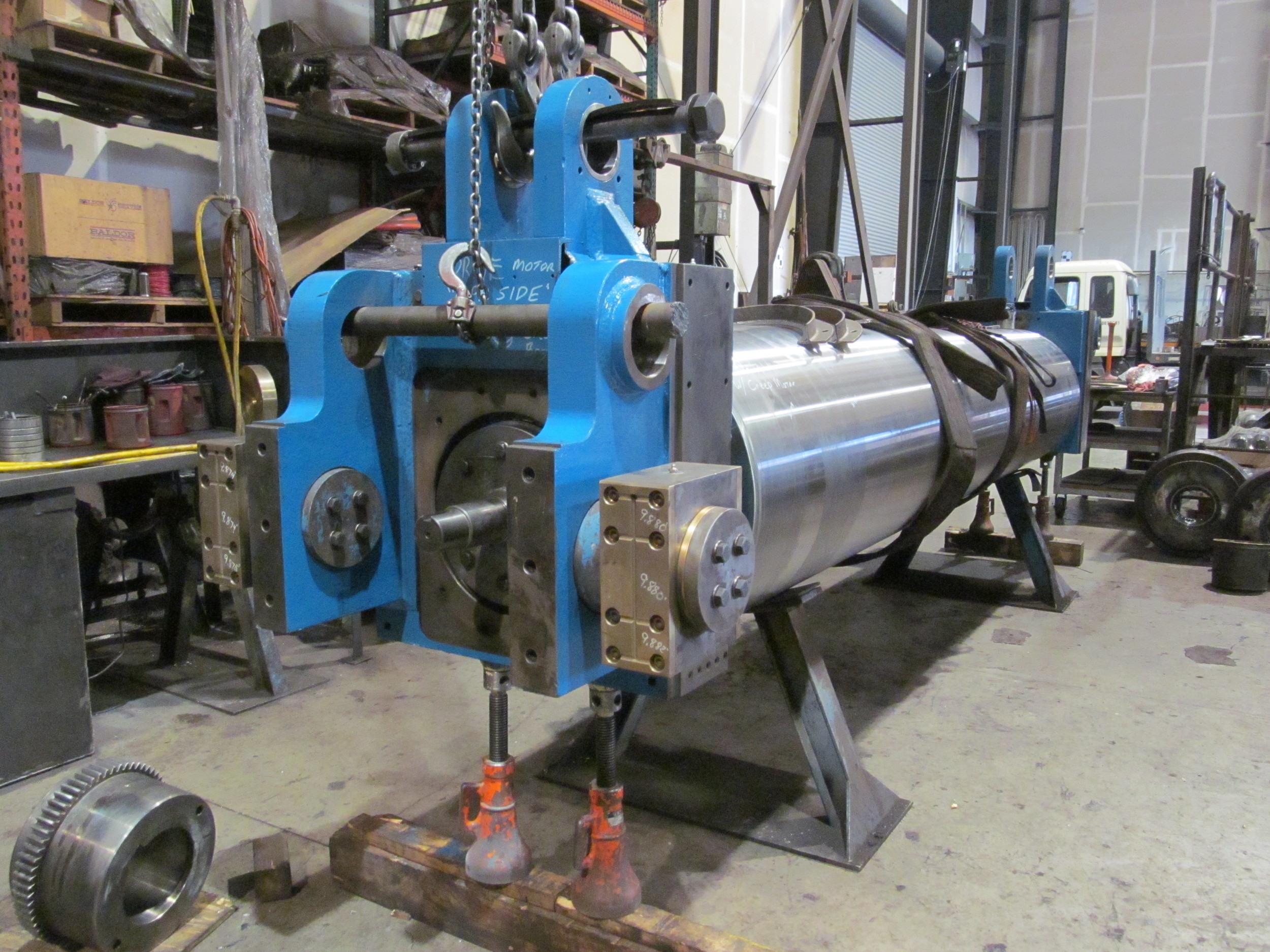

Machine component fabricated and machined in our facilities prepared for shipment.

Close up of machined features and assembly details on a large machine component manufactured complete.

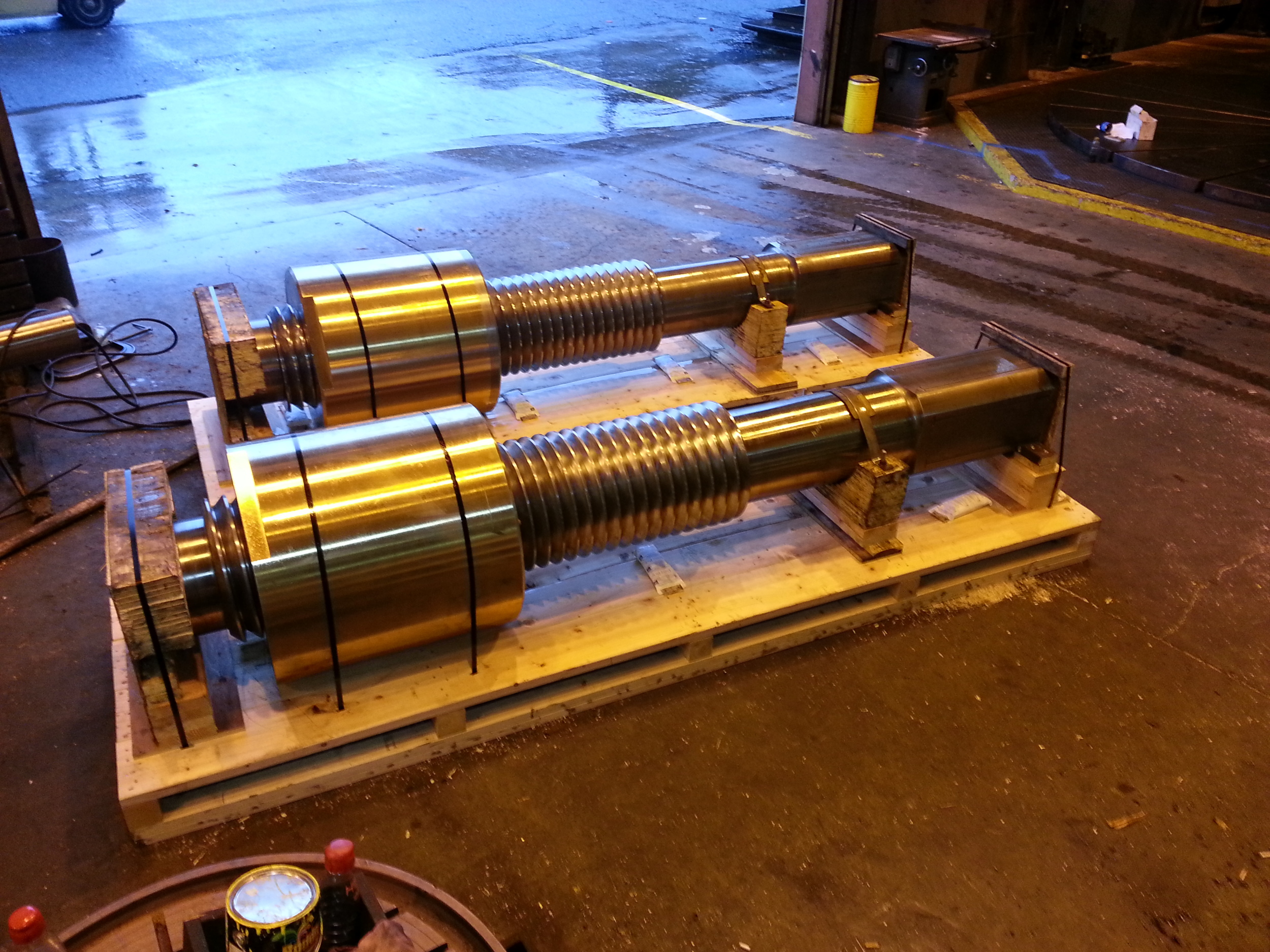

Top view of a 4 start acme thread in a dredge component.

Large Machine component with internal circular features being turned in our 22 foot capacity CNC vertical boring mill.

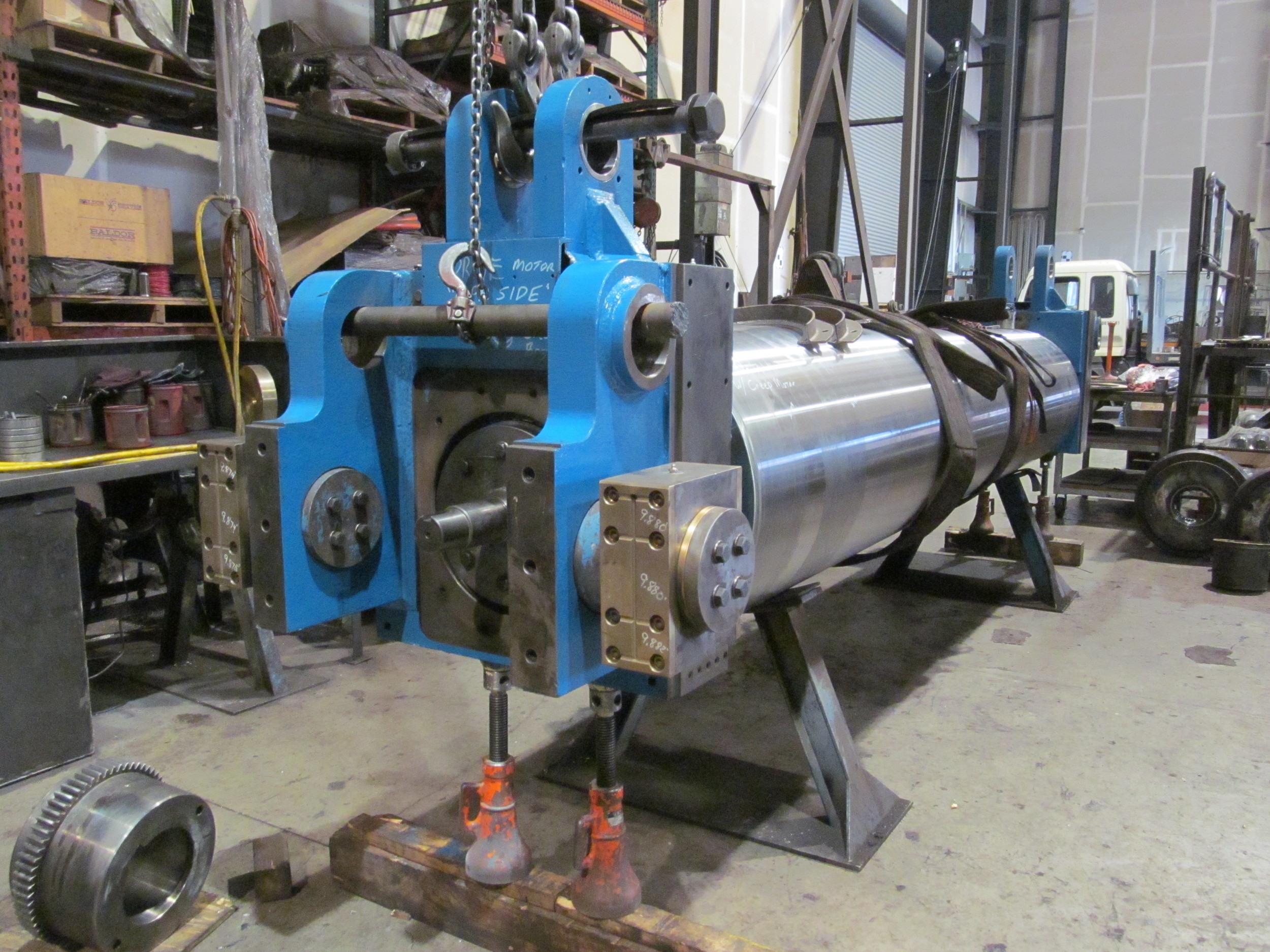

Coiling mandrel completely rebuilt including machining of replacement parts.

Leveller roller rebuilt and assembled for the steel rolling industry.

Vertical column, part of a custom machine fabrication at paint prior to delivery.

Circular features in a fabrication turned to dimension in our CNC vertical boring mill.

Fabricated machine component with a variety of features machined on our largest horizontal CNC milling machine.

View of hole details in heavy fabrication machined on our largest horizontal CNC mill.

Careful machining after stress relief and paint to assure flatness and final result in tolerance.

Portable milling machine components after finish machining.

We offer rock crusher repair and rebuild often improving on original perfomance and durability.

Commuter rail bogie that was machined on our medium sized CNC vertical planer mill.

Forging die machined to customer's exact specifications.

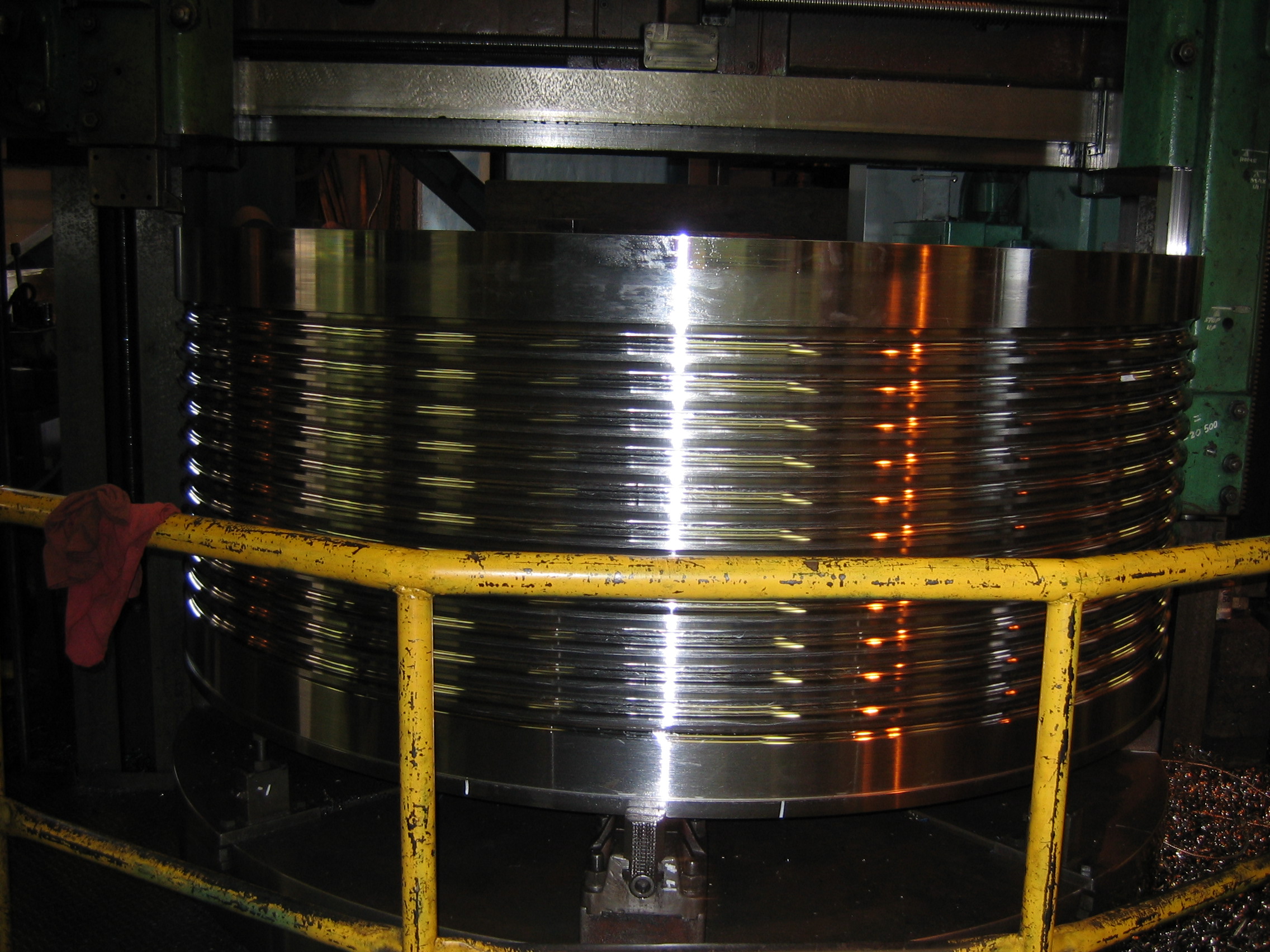

Manufacture as well as repair of all rolls for steel and paper industries as well as others.

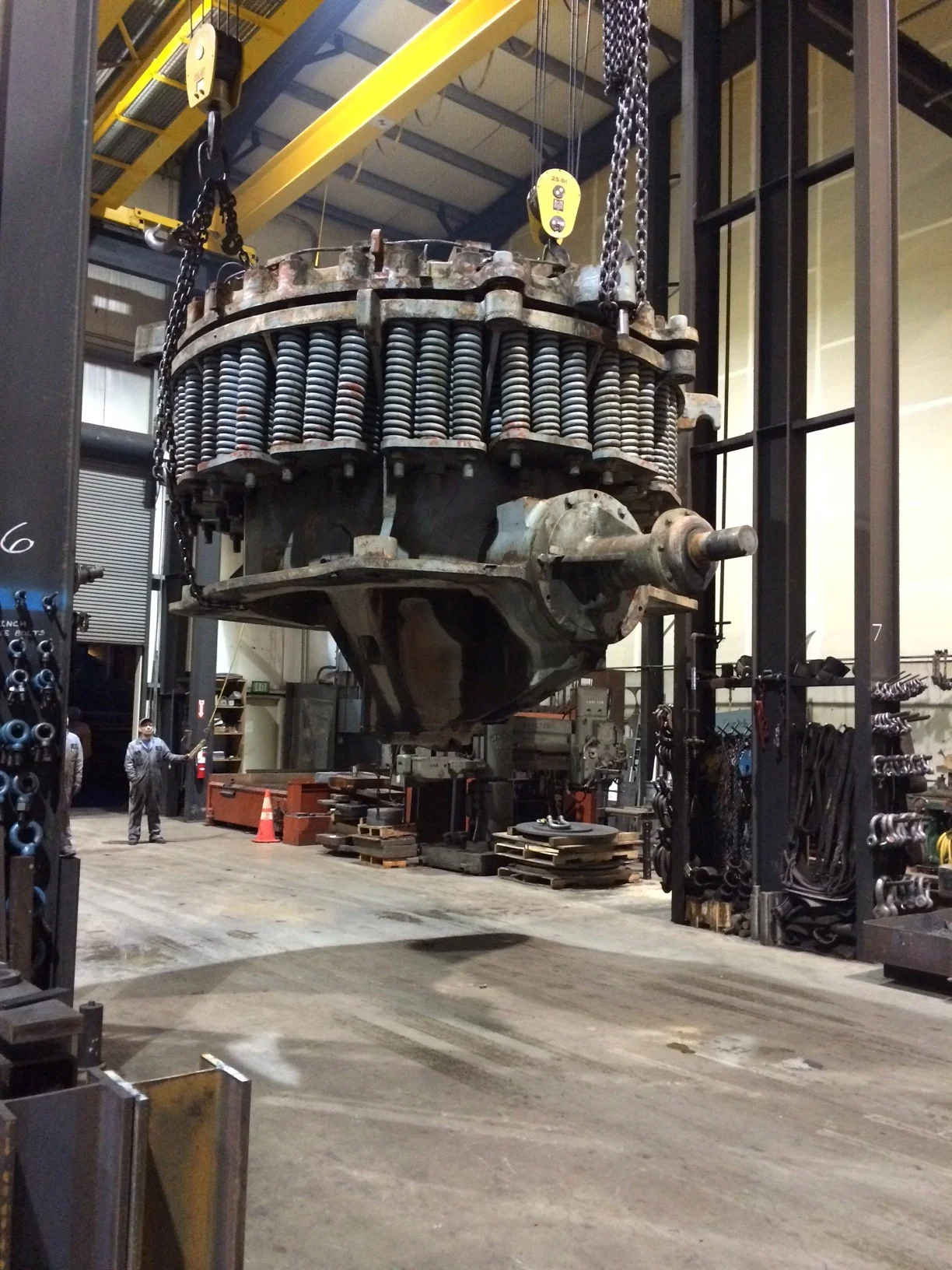

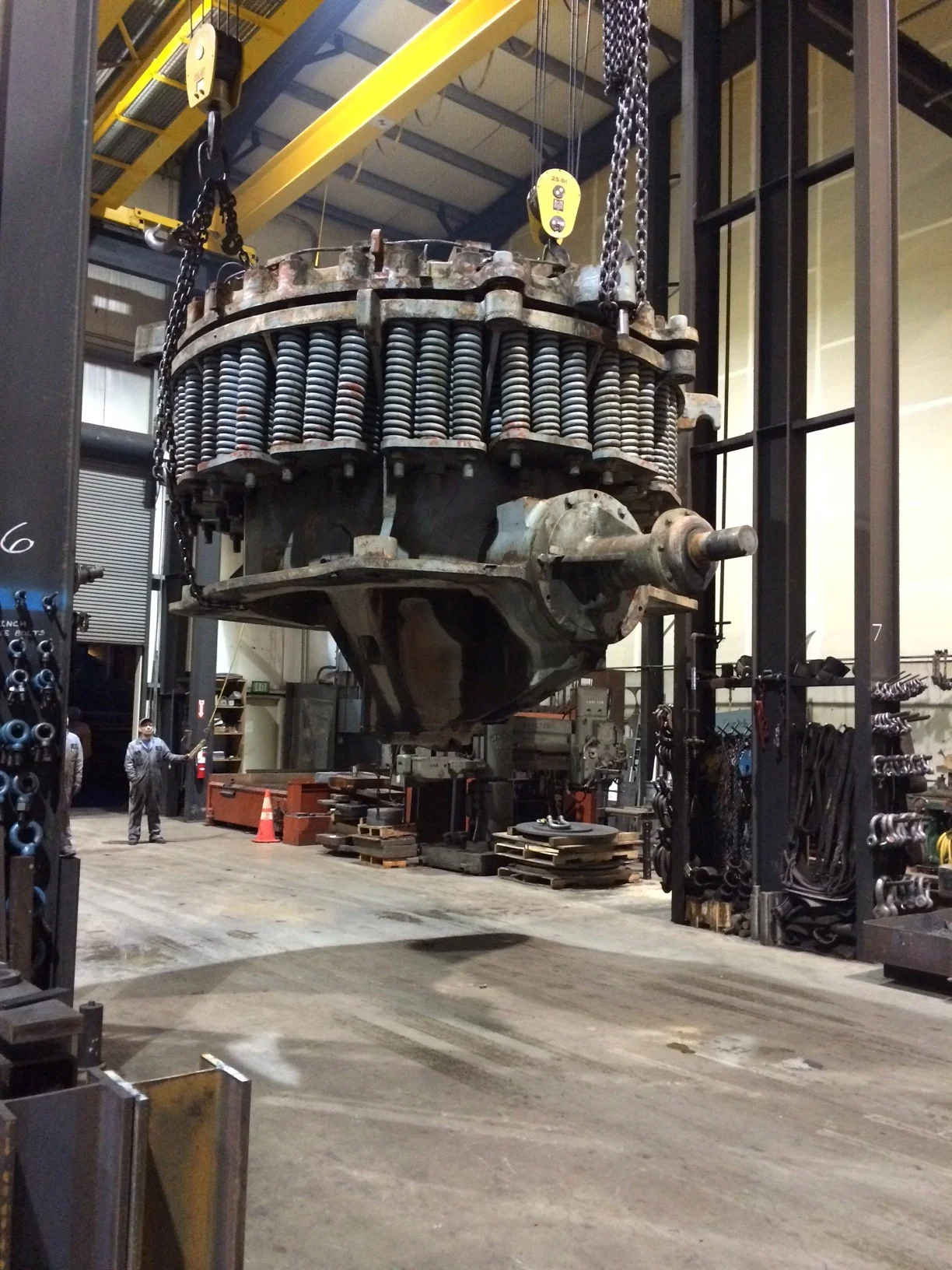

Complete tear down and rebuild of a rock crusher including hard facing and machining of wear parts.

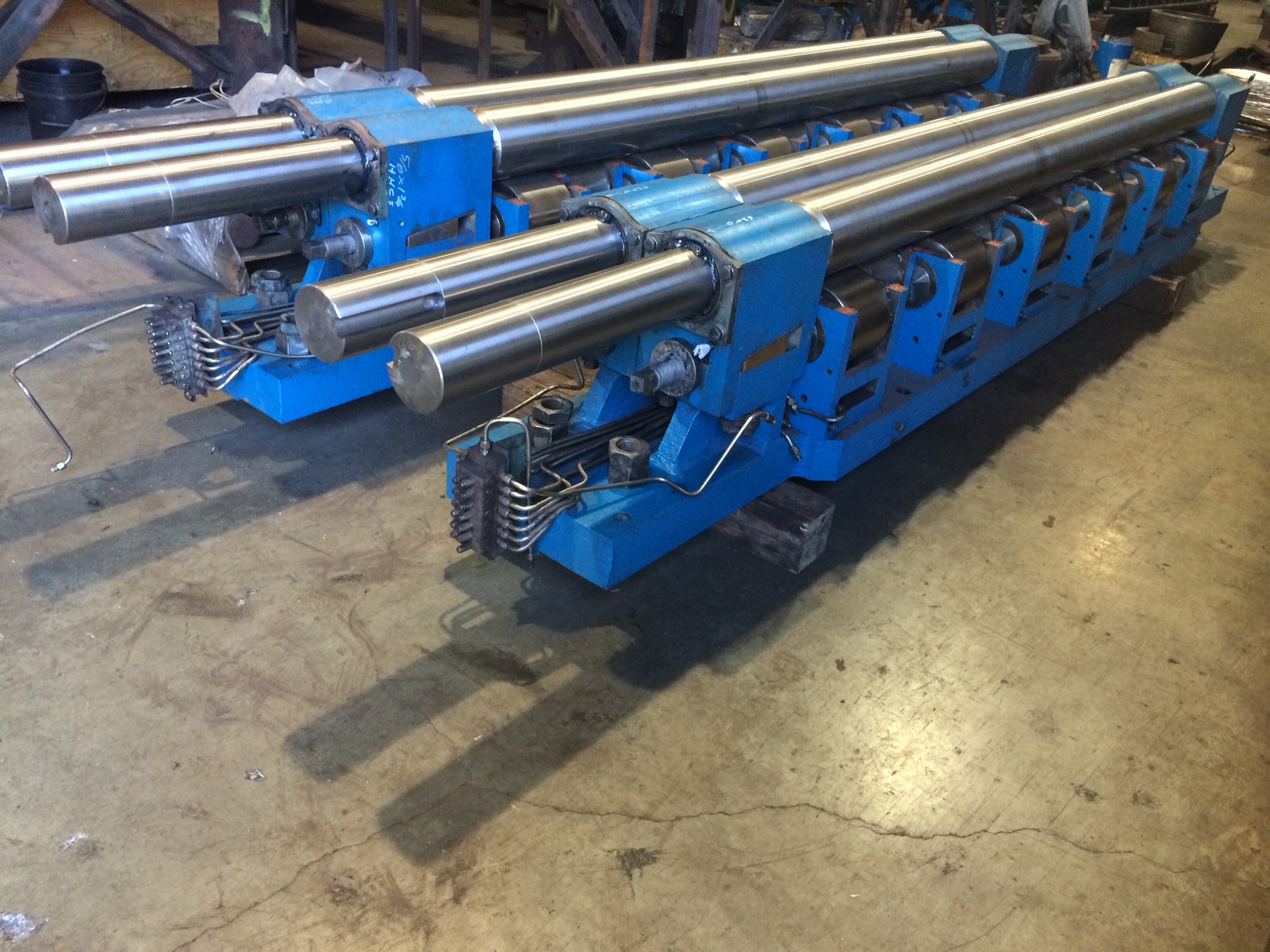

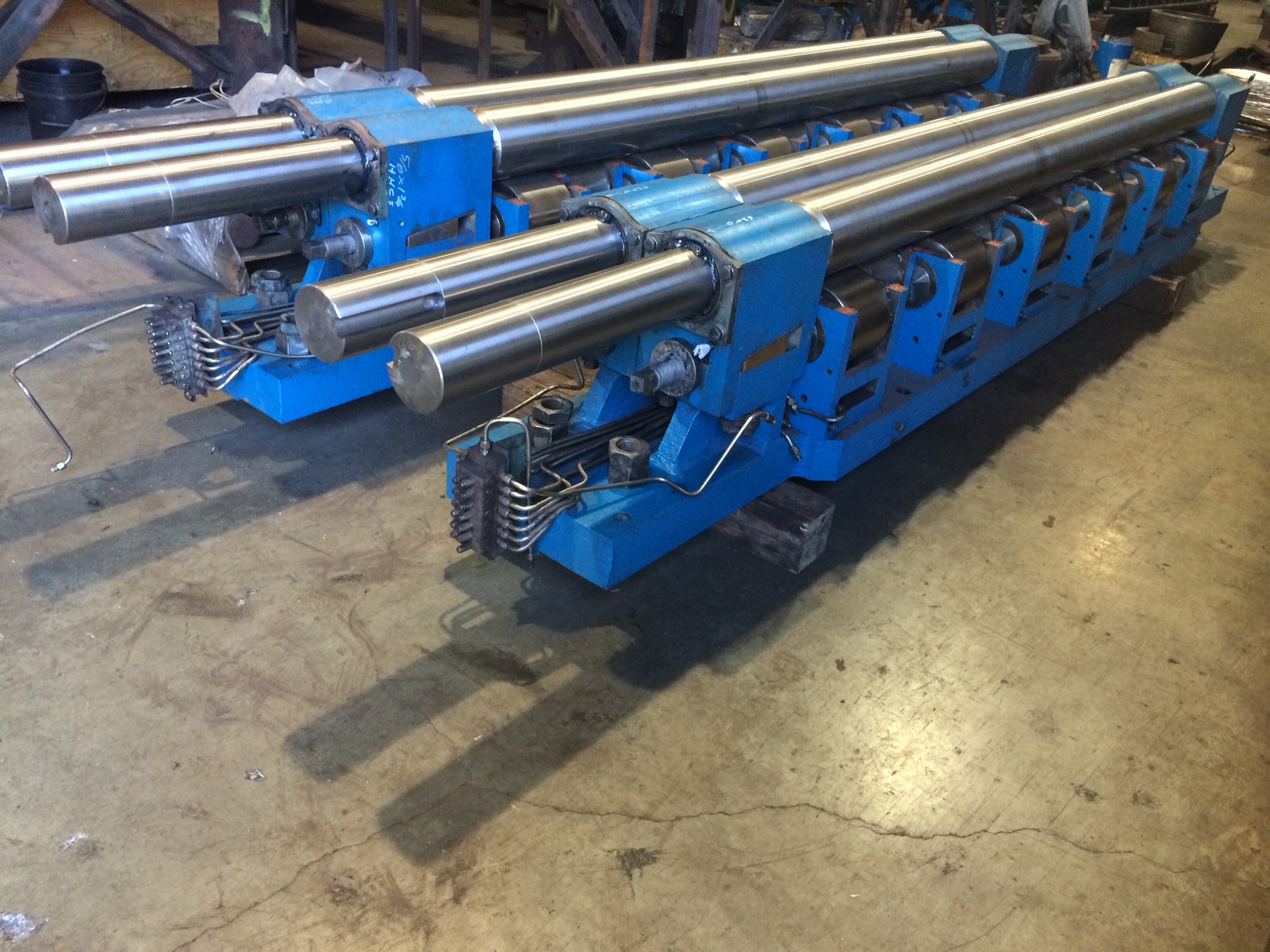

Idler rolls, back up rolls, drive rolls, we have the equipment and expertise to repair or manufacture your rolls to your specifications.

Steel shredding head, all parts machined and assembled complete in our facility, shown without wear parts installed.

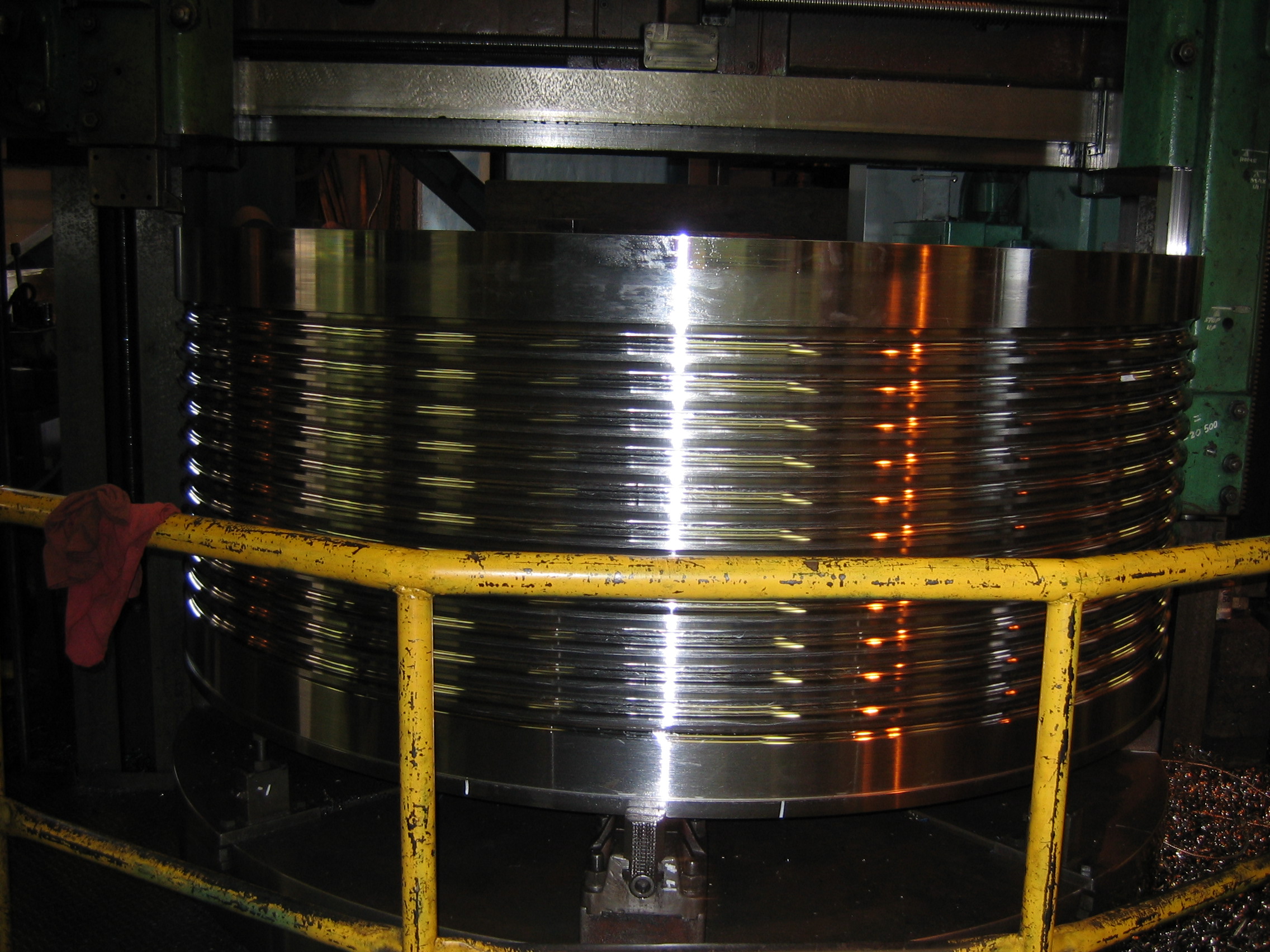

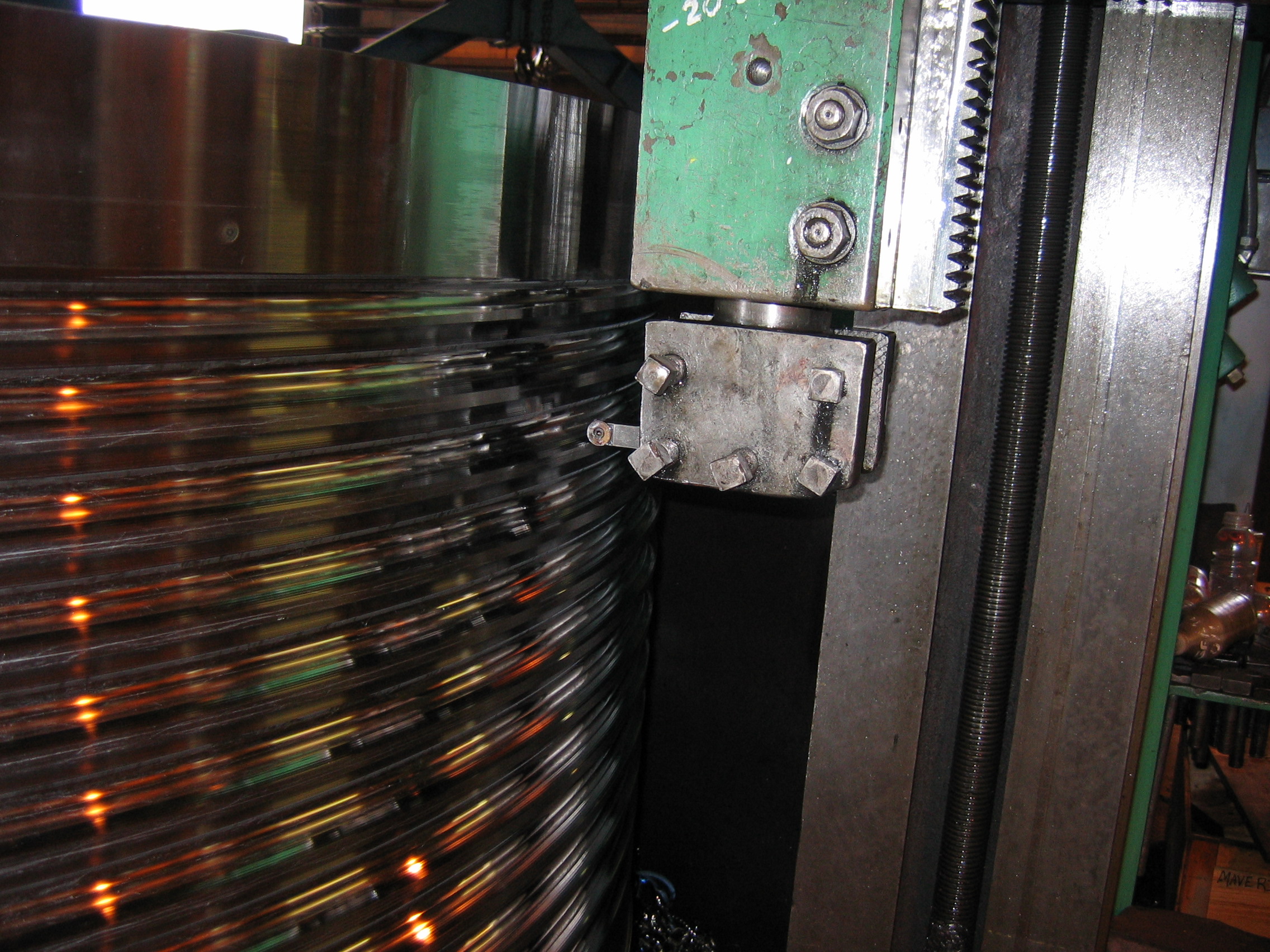

80 ton take up roll with bearing assemblies, 4 axis machining of chevron pattern.

Steel mill roll chevron milling, bearings left mounted to serve as rotational axis.

Special challenges of controlling such a large moving mass to CNC machine this intricate pattern.

Rock crusher parts require hard facing and weld repair to return them to service. Our robotic welder lays down consistent beads for higher quality final surface.

Cone crusher weld repaired and then CNC machined back to original specifications.

Crusher parts sustain severe wear and damage that we can weld repair and re-machine.

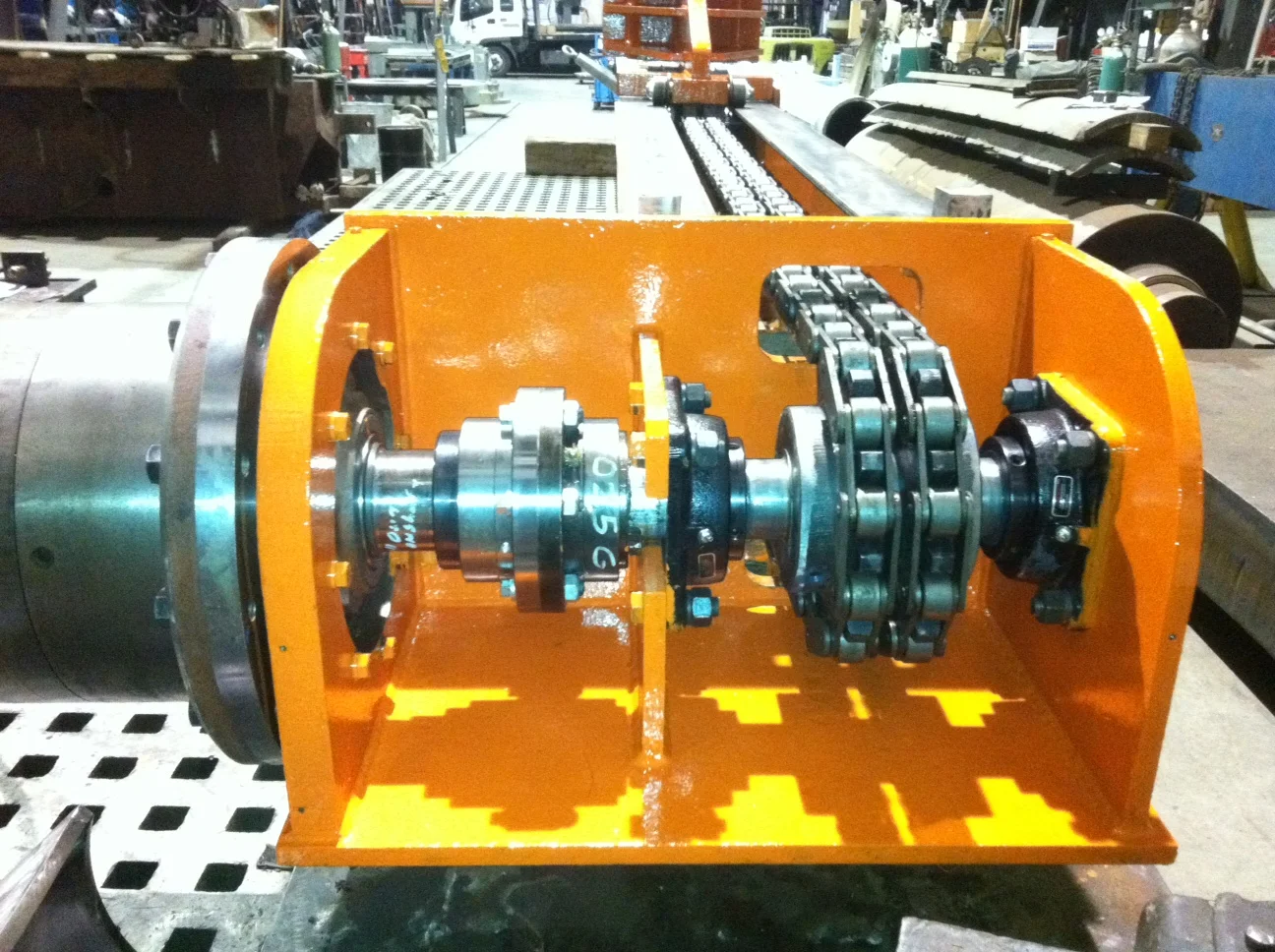

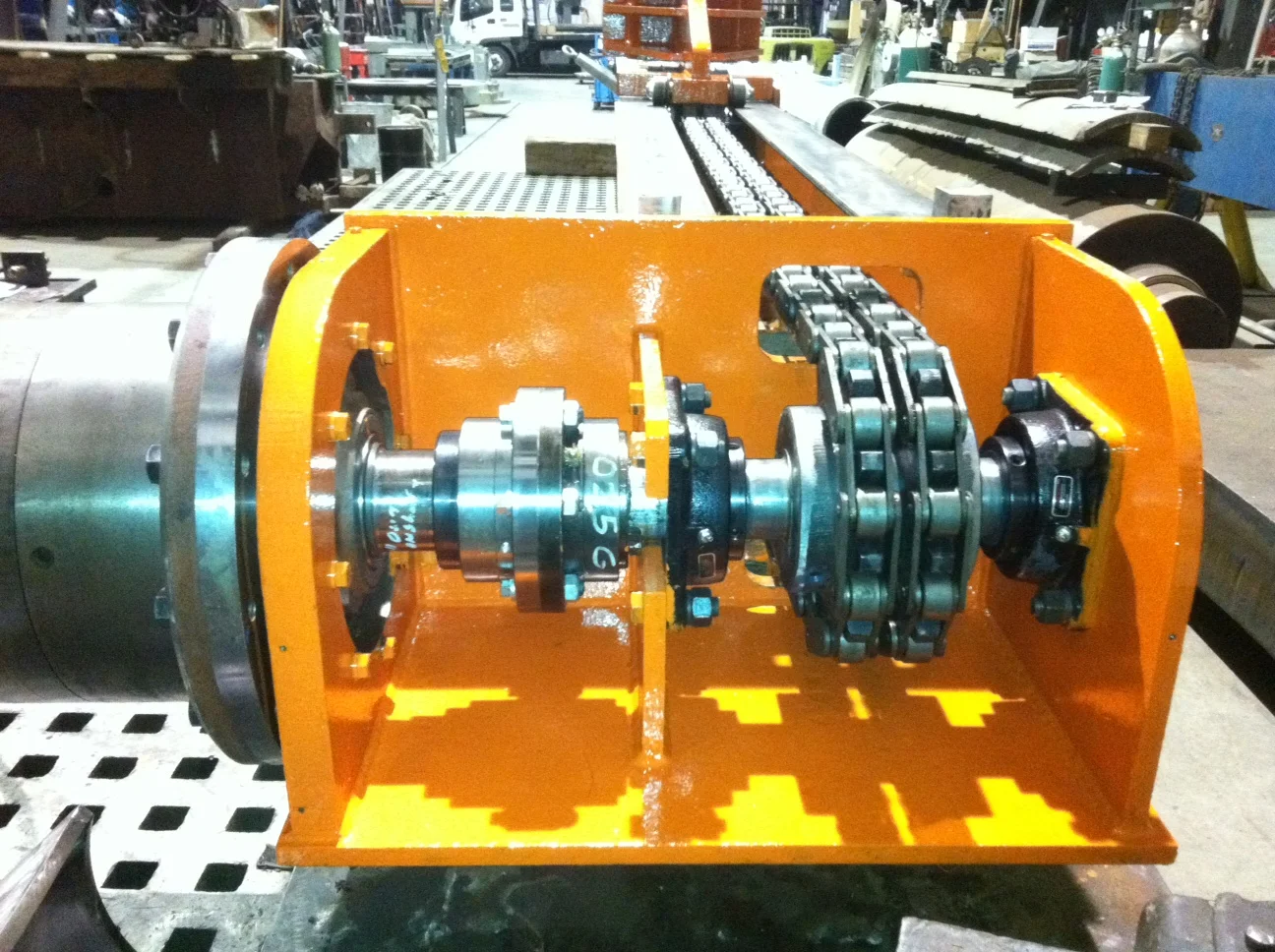

Transmissions, drives, gears, belts and bearings for heavy industry, we can design and build to your specifications.

The modern world is built on crushed rock, we keep your equipment functioning at its peak.

We can manufacture all new armor plate components as well as repair your existing parts depending on the severity of damage and wear.

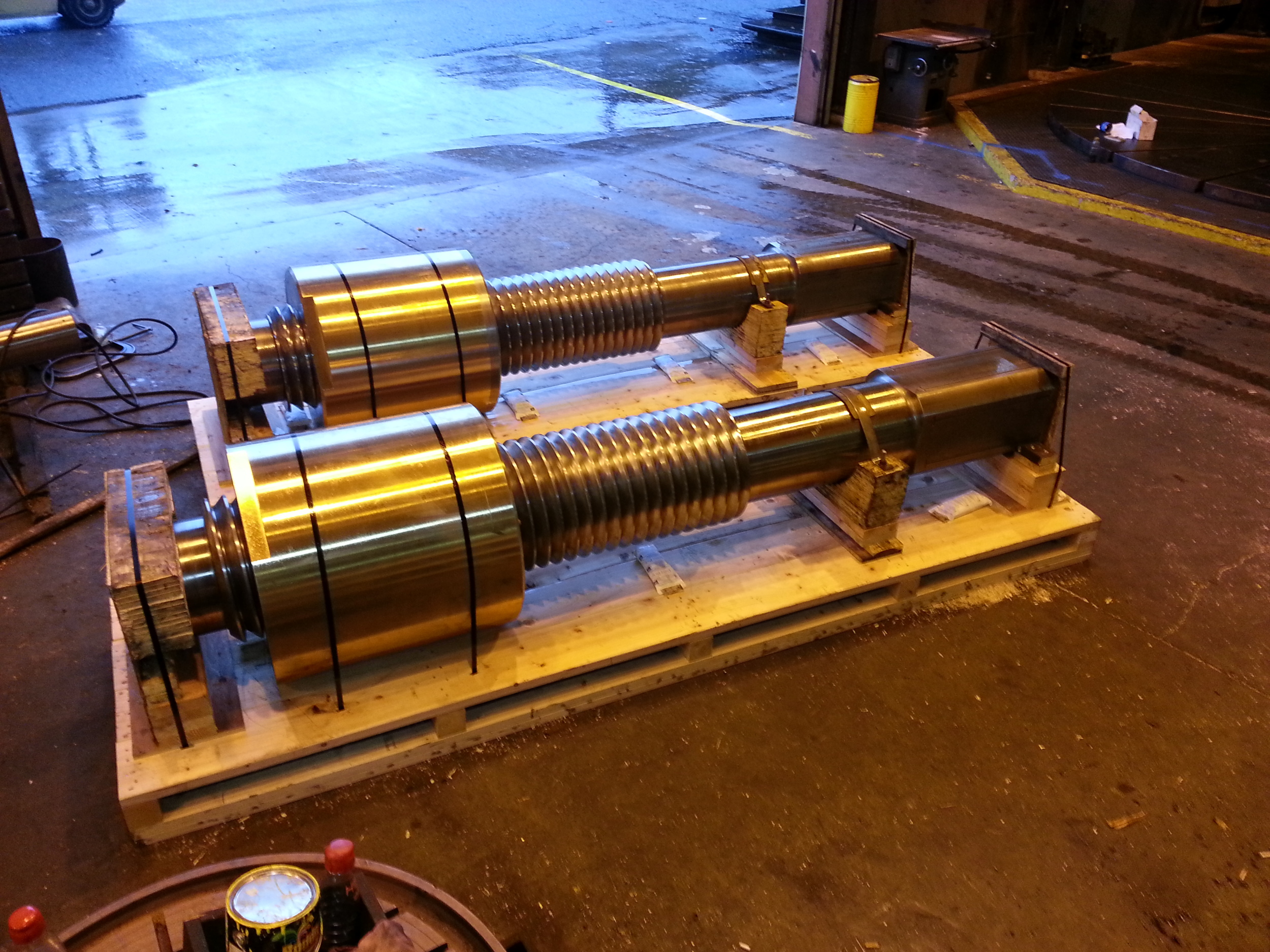

The largest and heaviest parts move in and out of our facilities daily. Rolls, spindles and shaft are our specialty.

A storage and handling rig for backup steel mill acme shafts and nuts assure that parts remain undamaged and ready for quick installation.

Buttress threads for holding heavy loads can be CNC machined for your specific application.

Line Bore

If you can think it up or at least describe to us what you want to do, then we can think it up, design it, engineer it and then manufacture it. Solving problems with creative solutions and iron and muscle is what we have been doing since 1917.

Pinch rolls assembled and shipping back to the customer.

Furnace gate set up on our largest vertical CNC for machining of critical features.

Let us fabricate and machine structural members for your next custom machine build.

Jaw crusher bore has been machined, sleeved and machined again.

Specialized conveyor for the paper processing industry.

Up close on the conveyor rebuild.

Setting up to weld wear areas is part of the rebuild process.

Rock crusher mantle welded to a temporary fixture so the wear areas can be CNC machined accurately.

An aluminum stretcher head is 80,000 pounds of steel welded and machined.

Details of machining performed on the stretcher head, large surfaces must be flat for a high quality installation.

Manifold assembly and welding requires attention to detail and proper procedures to make sure threaded components function as designed.

Plywood, OSB and MDF hot plates need an occasional refurbishment. We can straighten, weld, machine, leak test and return your old and worn hot plates to work like new.

Robotic welding and positioning equipment allow us to put the right weld in the right spot at the right heat at the right depth, and it just looks cool.

Disassembled components staged for re-assembly of a leveller for a steel mill.

Rigging and moving the largest rock crushers takes knowledge and skill to perform safely and to protect the customers equipment.

Lifting rig that is an accessory part of a specialized aerospace specific machine.

Steel mill shear built brand new will have many years of severe service.

Ship propeller safely loaded onto our CNC vertical boring mill.

Irregular shaped parts, like this stainless steel ship propeller, are the most difficult to hold on the machine and when flipping over.

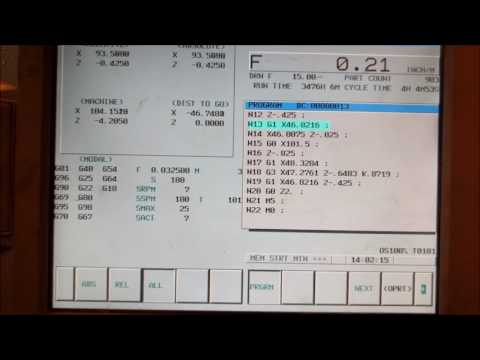

A full CNC retrofit and machine rehabilitation allows this customer to efficiently machine their large parts.

We will build or rebuild a machine from the ground up.

Up close, using CNC positioning to pick up existing features on a part and machining to match.

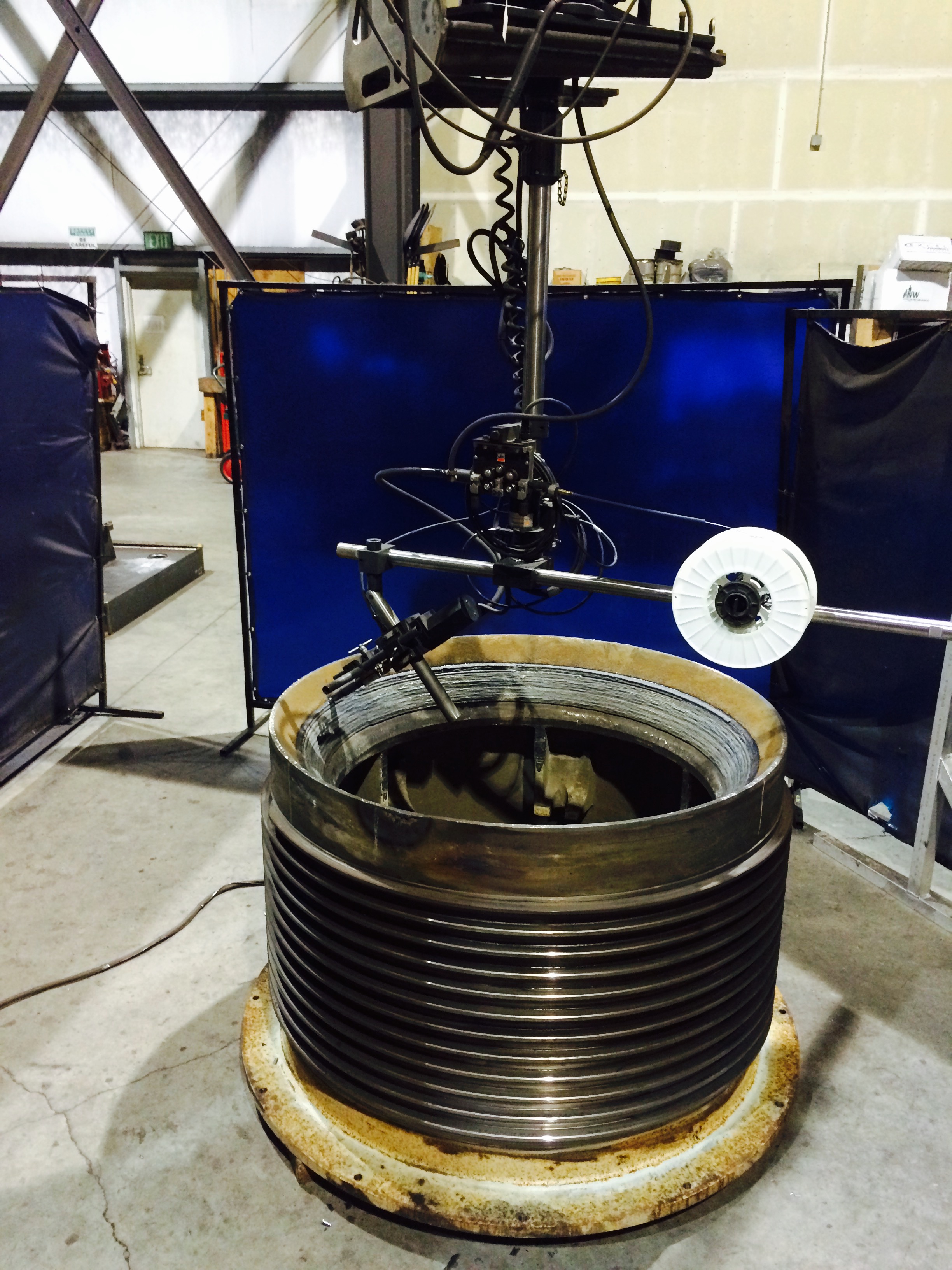

Wire rope drum remachining of rope grooves to refurbish an expensive part.

A diverse mix of product from steel mill backup chocks to marine propellers, all in the same day.

Customer requirements vary from thin, hollow and delicate to thick, massive and heavy. We have to be prepared to change our approach from moment to moment.

This petroleum pump base had to be inverted to machine the bottom flat, at 14' wide, this will only fit on 1 machine.

Multi start Acme threads are generated by CNC tool path and not a form tool. The flank angle, pitch and root are all independently machined and controlled.

We do it all, the fabrication and machining but also the engineering, the mechanical, electrics and electronics, assembly, we do complete projects from start to finish.

Sometimes the entire machine must be machined. It is most efficient to mount the entire rock crusher housing in the machine.

A line boring fixture fabricated and machined to tight tolerances.

Bearing plates with oil grooves machined from bronze.

We machined this component for a specialized machine used in building submarines.

Machine bases, towers and other structural components function better and longer in service when CNC machined to exacting tolerances. More closely aligned features mean less wear when in motion.

Ways for a portable milling machine must be accurate and flat along its entire length.

Machines that we build combine all of our competencies from machining and engineering to assembly and testing.

A work roll for the steel rolling industry during final assembly

We also make smaller parts like these lifting hooks for a steel mill customer.

Curved machine ways for a portable machine tool built in segments.

A steel mill ram with newly machined ways being assembled.

Belt grinding a work roll to final tolerance and micro finish. Chrome will be added to increase service life.

Leveller rolls after assembly.

An oddly shaped saddle for a steel mill can only be machined in our largest CNC mill.

Burned out and welded together, now ready for machining.

Large excavating shovel dump block machined from steel castings and fully assembled.

Steel rolling mill edger wheel assembly completely refurbished at our facilities.

A new work roll for a titanium rolling mill with spline machined on our CNC vertical planer mill.

Complex fabrications are our specialty, minimizing twist and bow at this stage is critical.

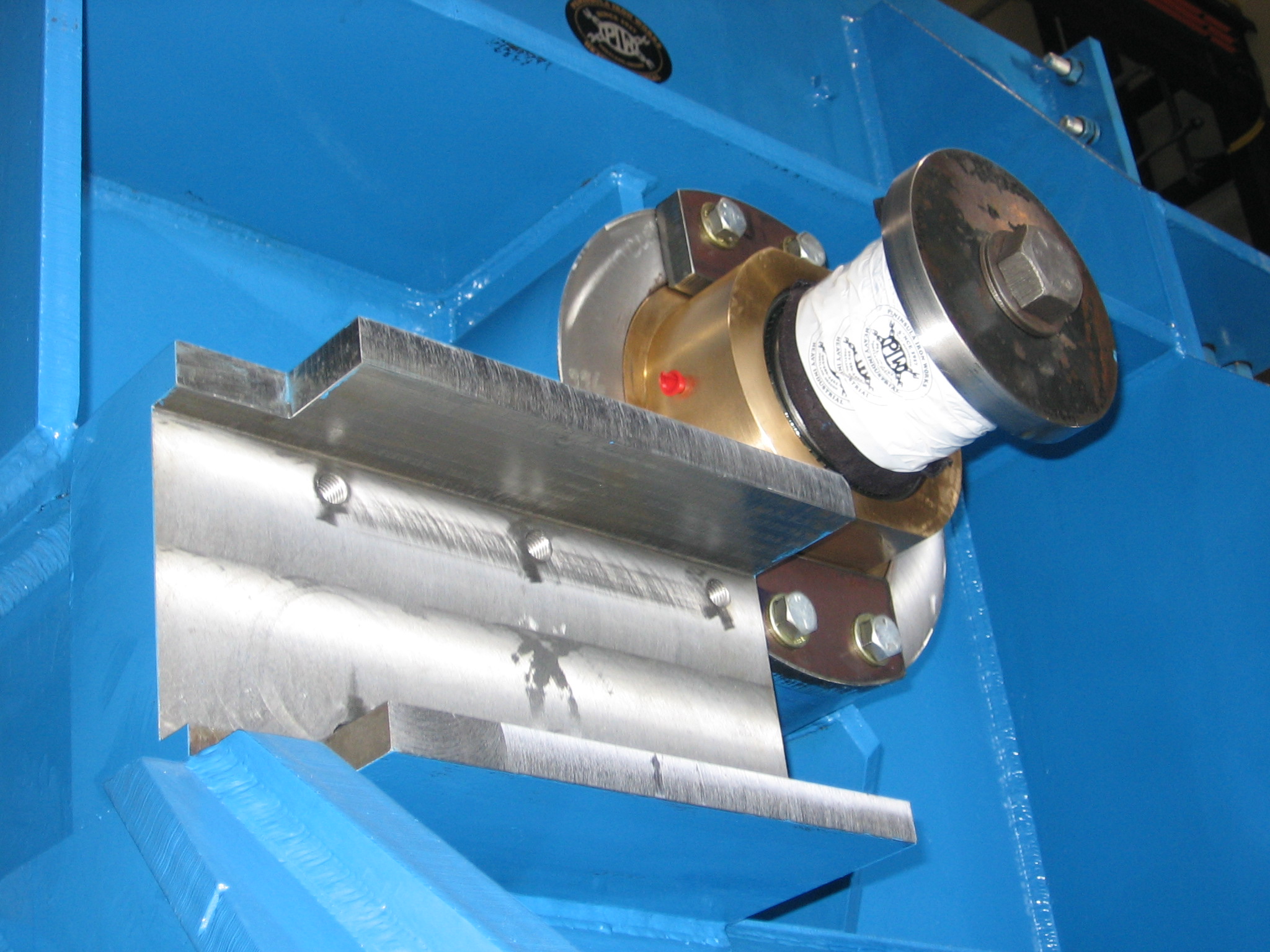

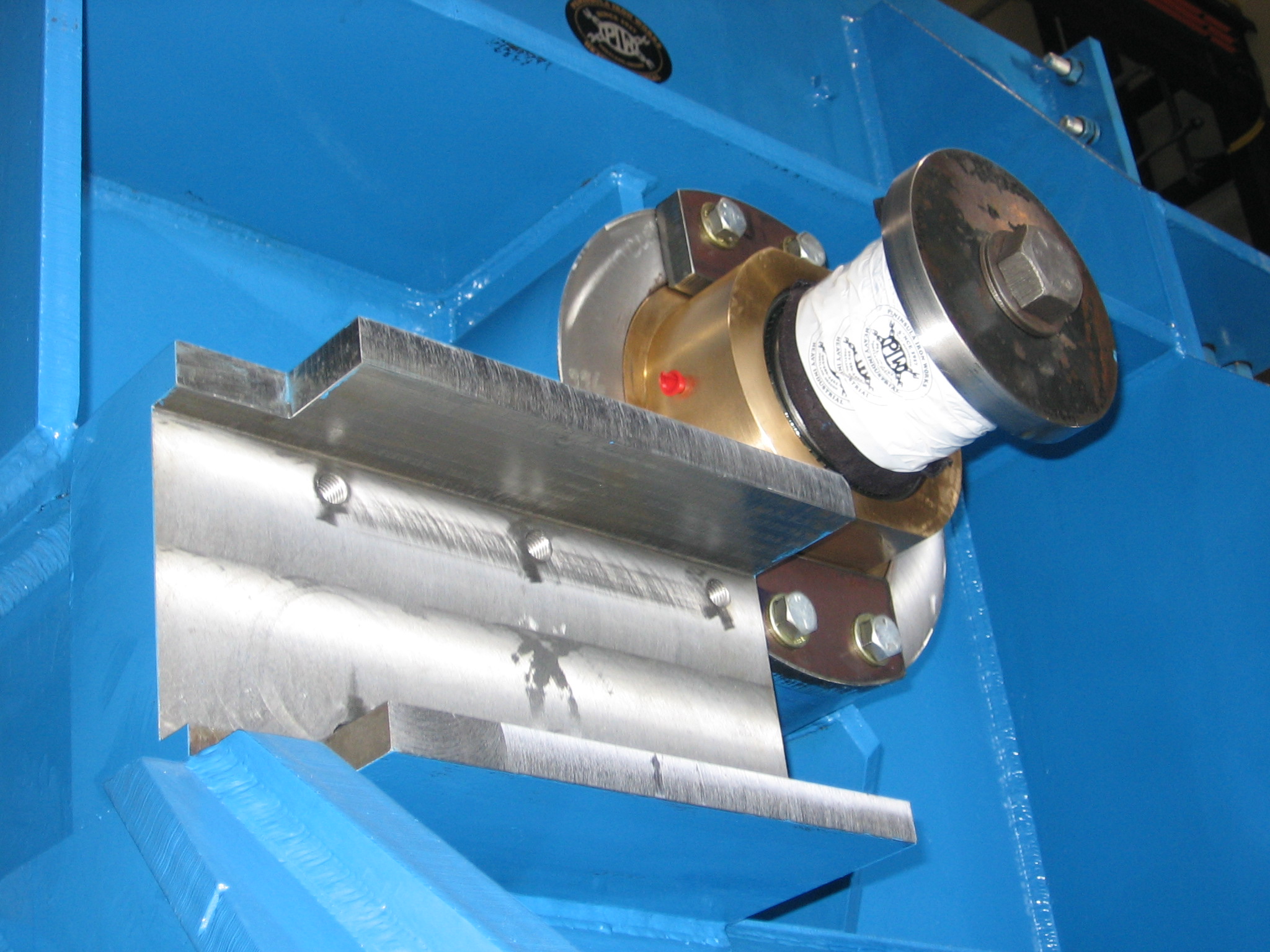

Safety Stop

Engineered, designed, manufactured and installed by PIW to prevent material from moving backwards at a pinch point. 2- 3" diameter pins extend by pneumatic cylinder, downturn fins to keep smaller pieces from falling between the rolls.

Bowl Lift

Modified this bowl lift by adding 4 feet to its height and travel to accommodate a modification to the production line which required a higher discharge point. Commercial food production line.

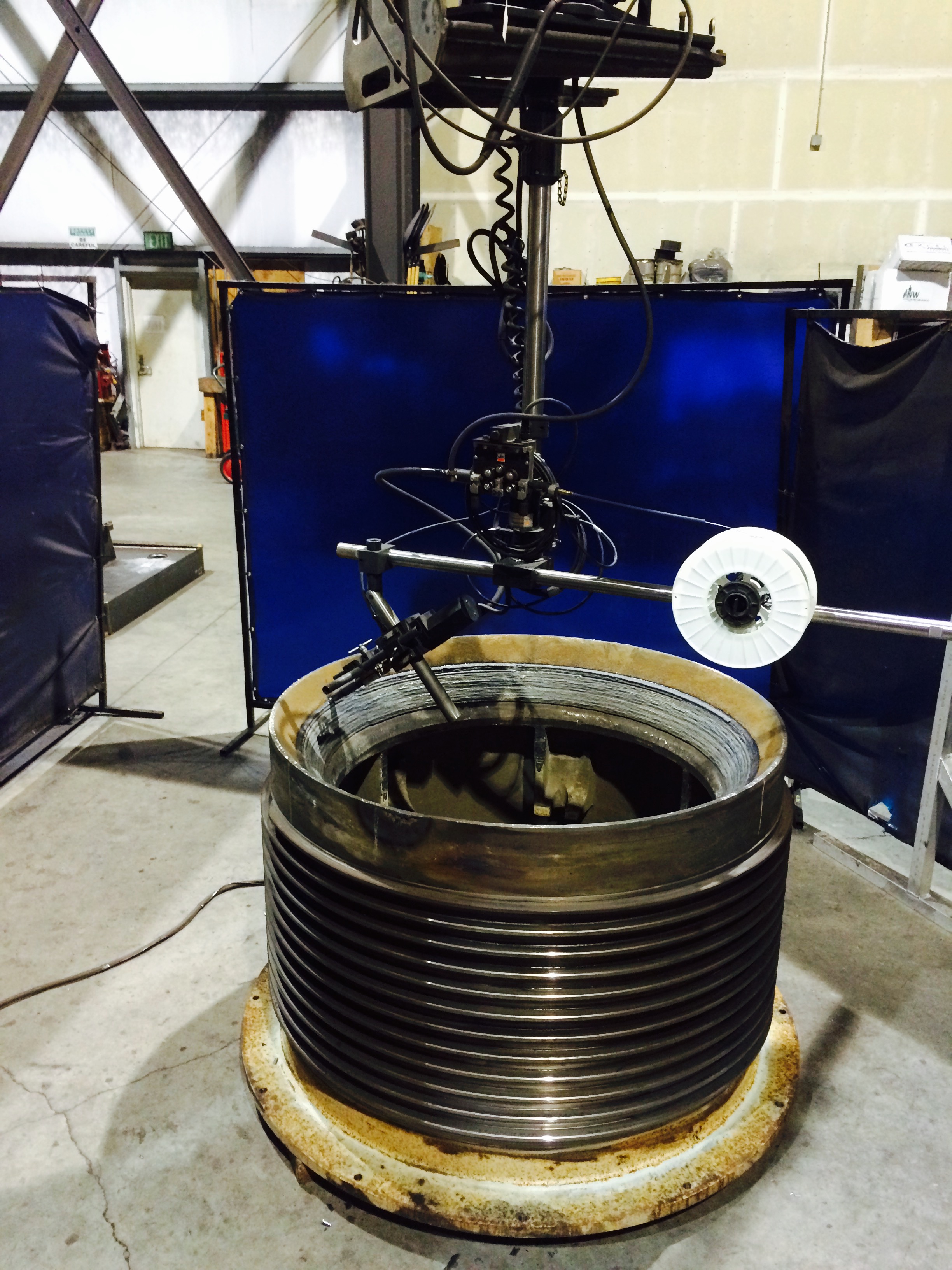

Wire Rope Drum

Close to 20' in diameter this wire rope drum is for a lock system at a dam on the mighty Columbia River, after many decades of service a rebuild was required. This is one of the only machines in the region that can handle a part this size, and it is CNC controlled which makes the machining of the internal features of the bore much more likely to be successful since there is no way to see what is happening 6 feet down inside the bore while the outside diameter is spinning past you at over 1,000 feet per minute.

316 Stainless Fabrication